+91 98253 18370

Products

+91 98253 18370

Products

|

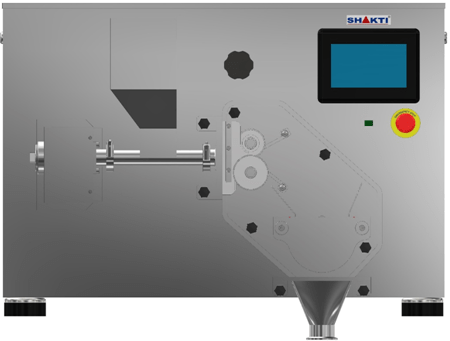

Model |

SRC-60 |

SRC-120 |

|

Working output (Depending on Powder, Hardness & granule size) |

5 kg/hr |

5 to 40 kg/hr (Lactose) |

|

Roller Diameter & width (Fitted Corrugated with machine) |

60 Ø x 25 mm |

120 dia& 40mm width |

|

Maximum Pressure force on Roll |

4 kn/cm |

20 kn/cm |

|

Roller Gap (Manually Set) |

0.5 to 3 mm |

0.5 to 4 mm |

|

Roller Speed |

2 to 18 rpm variable |

2 to 15 rpm variable |

|

Feed Screw Speed |

20 to 100 rpm variable |

10 to 100 rpm variable |

|

Oscillation Granulator Speed (angle range 30°- 360°) |

10 to 100 rpm variable |

2 to 100 rpm variable |

|

Weight |

160 kg |

750 kg |

The material in form of powder passes through the two counter rotating rolls of roller compactor under very high pressure. As the volume decreases through the region of maximum pressure, the material is formed into a solid compact sheet or flakes of ingredients. These flakes or compact sheet of ingredients are reduced in size to obtain the desired grain size. The machine takes extra care to prevent the generation of fine during this process.