Pharmaceutical Lab Machinery Manufacturer, Exporter and Supplier

Shakti Pharma Tech – A renowned pharmaceutical lab machinery manufacturer, exporter and supplier.

Shakti Pharma Tech is a well-established pharmaceutical lab machinery manufacturer and exporter. We are renowned for offering highly advanced machinery to serve the needs of the pharmaceutical industry, pharmaceutical colleges, and universities, along with research & developments (R &D) purposes.

Based in Ahmadabad, India, We Manufacture and Export the best quality and competitively priced products to several countries, including Australia, Europe, USA, Far East and Africa.

Product Category

All Purpose Equipments

- Main Motor Drives

- Attachments For Main Motor Drives

- Universal Gear For All Purpose

- Coating Pan - Polishing Drum

- Filling & Dosing Equipments

- Mould For Suppository Lipstick

- Suppositories & Lipstick Unit

- Granulating - Dry & Wet

- Grinding Attachments-Ball Mill And Triple Roller

- Homogenizing Attachments

- Kneading Attachments

- Blending - Mixing Attachments

- Double Cone Blender – 1, 2, 3 & 5 Kgs (SDC)

- Drum Hoop Mixer (SDHM)

- Laboratory Mixer (SLM)

- Cube Mixer – 5 & 10 Liters (SCM)

- Octagonal Blender (SOB-5)

- Lab Mass Mixer (SLMM)

- Conta Blender (SCB-5)

- V – BLENDER – 1, 2, 3, 5 & 10 (SVB)

- Y – Blender (SYB – 2)

- Powder Mixer (Ribbon Mixer) – (SRM)

- Ribbon Mixer – Vacuum Jacketed (SRM+VJ)

- 3 Dimensional Shaker Mixer / Blender – Model (S3D)

- Double Cone Blender – 1, 2, 3 & 5 Kgs (SDC)

- Lab Sheronizer (GMP) Lab Model

- Lab Extruder (GMP) Lab Model

- Sieves-Analysis Attachments

- Pelletizing Attachments

- Stirring Attachments-Planetary Mixer

- Friability Tester

R & D And Pilot Scale Equipments

- Models For R & D Labs

- R & D Rotary Tablet Press For Lab & Mini Production

- Single Rotary Tablet Press (Lab Press-1) (SLP – 1)

- Single Rotary Tablet Press (Lab Press-2) (SLP-II)

- Tablet Press Fully Instrumentation – cGMP (PILOT 200)

- Single Rotary Tablet Press (Lab Press-1) (SLP – 1)

- R & D Bi - Layer Tablet Press - Pilot 200 - DL

- Rotary Tablet Press Machinery For Pilot 300-(20D,27D,33BB)

- Rapid Mixer Granulator R & D Model-Pilot Scale

- Fluid Bed Processor R & D Model

- Fluid Bed Processor (3,5,10 KG) – MODEL – SFBP

- Fluid Bed Processor PLC Table Top – GMP Model (SFBP – 500G & 1Kg)

- Fluid Bed Processor (3,5,10 KG) – MODEL – SFBP

- Fluid Bed Dryer R & D Model

- Fluid Bed Dryer Table Top GMP Model (SFBD – 500G & 1 Kgs)

- Fluid Bed Dryer (1 TO 5 Kgs) R & D Model (SFBD-1, 2, 3, 5 Kgs)

- Fluid Bed Dryer Table Top GMP Model (SFBD – 500G & 1 Kgs)

- Tablet Coater Tabscoat-M-R & D Model & Pilot Scale

- Tablet Coater Tabscoat – (12, 16 & 19, 24, 30) (SAC-12″, 16″,19″, 24″, 30″)

- Tablet Coater Tabscoat Polot Scale – (48″ & 60″) (SAC)

- Tablet Coater Tabscoat – (12, 16 & 19, 24, 30) (SAC-12″, 16″,19″, 24″, 30″)

- R & D Coating (Convensional) System With Pan

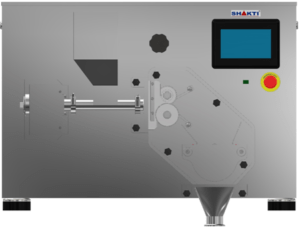

- Rollcompactor & R & D Model

- R & D Milling & Size Reduction Model

- Multi Mill Vertical – GMP Model (SMM)

- Lab Cone Mill R & D Model (SCM)

- Lab Communicating Mill R & D Model (SCOM)

- Lab Oscillating Granulator – ACVF R & D Model (SOG)

- Multi Mill Vertical – GMP Model (SMM)

- R & D Lab Blender-Mixer Model

- R&D – 3D SHAKER (TUMBLER) MIXER

- Lab Double Cone Blender – 1Kgs, 3Kgs & 5Kgs (SVMD-DC)

- R & D Double Cone Blender – (10Kgs, 15Kgs, 20Kgs, 30 Kgs.) (SDC-30)

- Lab V – Blender – 1, 2, 5 & 10 Liters. (GMP Model) (SVB-10-MINI)

- R&D V – Blender (10-25 Kgs.) GMP Model (SVB)

- Lab Octagonal Blender (5, 10 Kgs.) (SOB)

- R & D Conta Blender GMP (SCB)

- R&D – 3D SHAKER (TUMBLER) MIXER

- R & D Tableting Allied Machinery

- Dies & Punches (All Types)

- Mini Vibro Type Shifter R & D Model (SVB)

- Dust Extractor (SDE)

- 6 Tray Dyer (STC)

- Manual Tablet Hardness Tester (SHT-20TP)

- Tablet Disintegration Unit (STD-20S)

- Dies & Punches (All Types)

- Capsule Filling & Loading Machine

- Colloid Mill R & D Model

- Homoginizer Stirrer – R & D Model

- Filter Press

- Blister Mini Manual Packing & Cutting Machine

- Clean In Place (CIP) Washing System